Setting the benchmark for excellence in plastic injection molding on a global scale

Our commitment to excellence and quality is unwavering, reflected in every product we deliver.

Our certifications

Injection Molding

Precision group

Pristine Precision!

ISO Class

8 Clean Room

Plastic injection processes and specialized packaging that adjust to your needs.

Injection Molding Perfected!

Expertise in Plastic Injection Molding and Tooling

Precision Group has a well-established reputation for providing fully integrated manufacturing solutions with an unwavering focus on precision and consistent delivery of high-quality services, serving clients around the world. Unmatched proficiency and knowledge in the art of plastic injection molding.

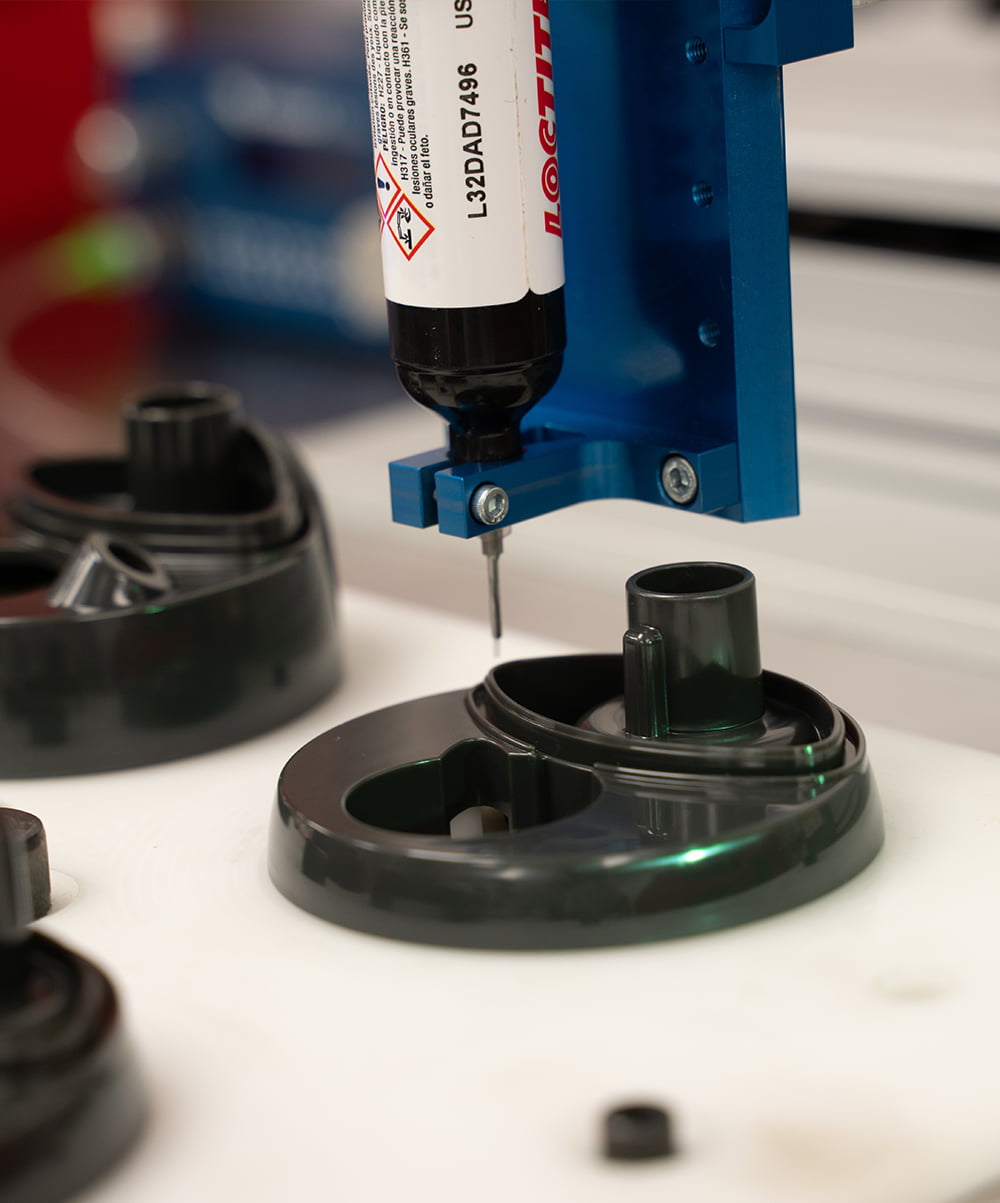

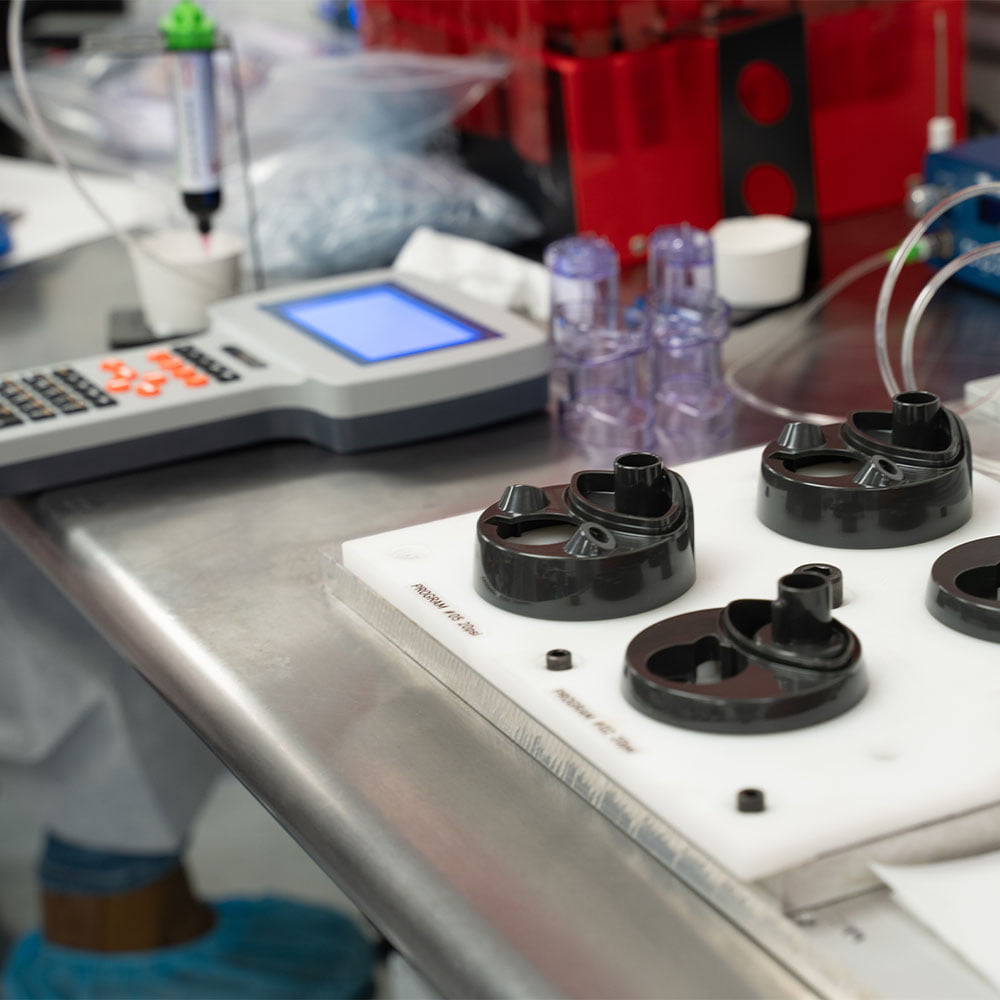

Our extensive experience in manufacturing for the Medical, Electronic and Life Science industries is bolstered by our in-house injection molding capabilities, enabling us to produce highly engineered parts with exceptional precision and tight tolerances.

Experience the pinnacle of injection molding excellence with our perfected techniques and cutting-edge technology.

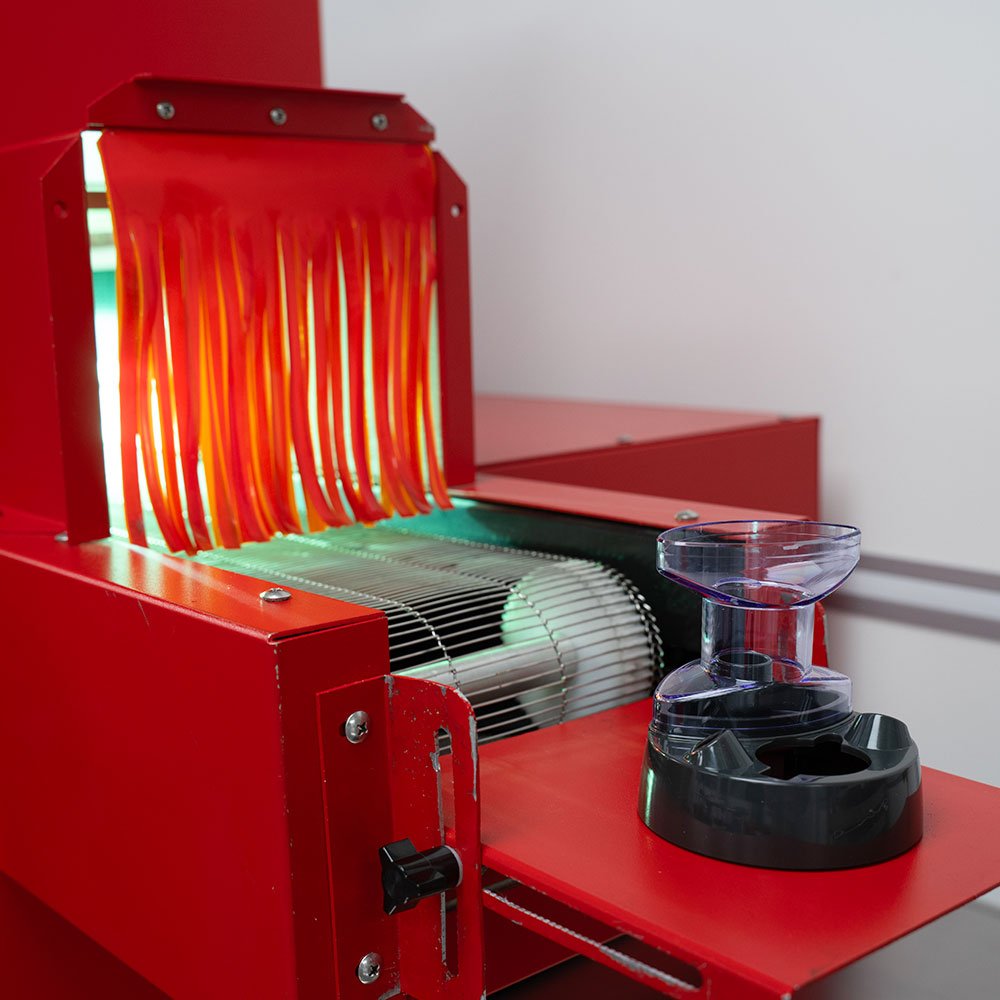

By utilizing our ISO Class 8 Clean Room for both molding and assembly, we are able to offer unparalleled quality assurance management throughout the manufacturing process of medical and electronic components and subassemblies.ISO 8 Clean Room Certifications

ISO13485:2016 and ISO9001:2015 Certifications at the heart of our manufacturing process is an unwavering commitment to ensuring unparalleled quality and precision.

We achieve this through our robust quality management systems, stringent GMP processes, and highly efficient program management procedures, designed to effectively manage the most complex, multi-tiered manufacturing specifications.

As your trusted reference for plastic injection molding solutions, we are committed to delivering exceptional results that elevate your products and exceed your goals.

Clean Room Molding Capacity

Climate Controlled Assembly and Packaging

Discover the unparalleled benefits of choosing Precision Group's ISO 8 Cleanroom for your manufacturing needs

Flexibility

Our inherent flexibility empowers us to quickly and seamlessly scale production to meet even the most demanding high-volume manufacturing requirements.

Seamless end-to-end manufacturing

Our ability to offer full operations on demand, including a comprehensive range of secondary services such as labeling and packaging, coupled with our in-house high-class manufacturing capabilities, sets us apart as a leader in the industry.

Automation

By leveraging the latest in automation technologies, we streamline component manufacturing processes to deliver highly competitive solutions that meet your unique needs and exceed your expectations.

You will find the answers to the most frequent questions that our clients usually have.

Cleanrooms are controlled environments where contaminants like dust, microbes, and other particles are filtered out in order to provide the cleanest area possible. Most cleanrooms are used for manufacturing products such as electronics, pharmaceutical products, and medical equipment.

Cleanrooms are classified into different types depending on the sterilization level of the environment. The cleanrooms are divided into 9 classes based on the number of particles per m3 that can be measured inside. They range from ISO 1, the most sterile room, to ISO 9, considered a standard cleanroom.

ISO 8 cleanrooms are used for pharmaceutical products, manufacturing medical devices, biotech and life-science processes, that’s why they need these requirements to provide the highest quality.

Ask Us a Question

If you do not find the answer you are looking for, do not hesitate to contact us and we will be happy to help you.

We are excited to embark on a new project with you. A dedicated member of our team will reach out to you and discuss your needs and requirements in further detail.